The post Dropped Object – High Risk Work Environments appeared first on USSA Global.

]]>When conducting any work on multi-level work areas it is very important to consider the interactions between activities i.e. Simultaneous Operations – Be aware of all other jobs taking place and if your work is going to be close to other work crews ensure you leave clear access ways for personnel and equipment to move around using barricades for any materials or equipment that may pose as a hazard to others.

- Drop Zones

- The drop zone is an area where equipment and tools may fall or be dropped during work activities.

- When determining the size of an area consideration should be taken into the height of the task, the distance items may be propelled, size of the tools and equipment and potential for objects to bounce.

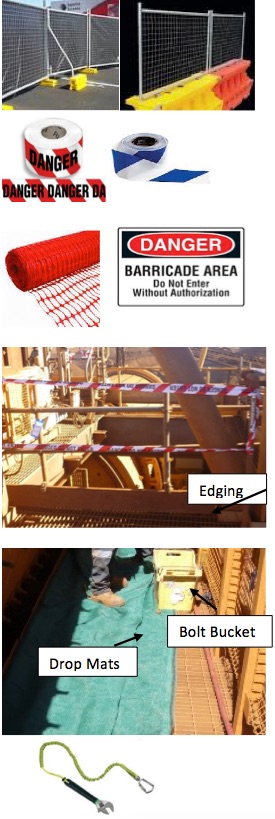

- Hard barricading should be considered the first option, if the work area is complex or does not allow it, use soft barricading materials

- This zone shall be barricaded with Danger tape. Where not practicable to do so a Spotter must be used in combination with exclusive control tape.

- Placement of barricades

- Attach barricading information tags that contain supervisor contact details, duration of the barricade and the specific hazard in the area

- Never enter a barricaded area unless you obtain authorisation

- Inspect work areas to ensure the barricades are maintained for the duration of the task

- Edge Protection

- Ensure adequate edge protection is in place around the working area.

- Ensure adequate edge protection to openings that could allow items to drop. (Grid mesh removal etc.)

- Do not stack equipment on top of each other so that they exceed the height of the edge protection or barricade.

- Maintain good housekeeping around work area during the task duration.

- Drop Mats, Bolt buckets

- Position Drop mats around work area where the flooring can allow for objects to fall through.

- The use of bolt buckets or containers are required to secure small objects.

- When determining the size of the drop matt, consideration should be taken into the size of the tools and equipment and potential for objects to bounce.

- Secure tools and Equipment

- Secure all tools or equipment to prevent them from falling/being a dropped object (lanyards, edge protection etc.)

- Place all hand tools in tool bag when not in use and secure.

If your employees are exposed to high risk work environments and you are not sure of the required risk controls contact us:

Tell: 08 6311 7043

Email: cservice@ussaglobal.com

The post Dropped Object – High Risk Work Environments appeared first on USSA Global.

]]>The post The Importance of Reporting Events, Hazards and Near Misses appeared first on USSA Global.

]]>- You don’t really believe the event or hazard you saw is really that significant and is not worth the time and effort to report

- You don’t see the hazard or near miss escalating to the point someone will actually be injured

- You see a co-worker doing something in an unsafe way but, you inherently don’t like conflict and would feel uneasy speaking up

- You are busy and really don’t have time to stop and report things right now

- You believe that if you do report something, you are going to be tied up with the report and will be under more pressure once done to catch up on the work you should have been doing

And there are many, many more reasons.

At-Risk-Behaviour

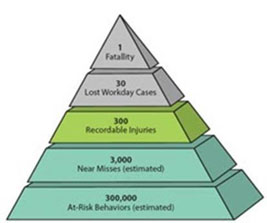

Figure 1 – Frank Bird Triangle

Frank Bird’s Tringle, was developed in the 1960’s. His conclusion was one thing led to another and ultimately resulted in something catastrophic eventually. His estimates of underlying at risk behaviours led to near misses and eventually events causing injury or harm to workers. Other researches explain a domino effect or the lining up of factors leading to an event.

Many have disputed this research and similar work by others but most people will agree the majority of workplace incident occurred because someone made a choice and that choice put them in danger. The choices we make are usually based on our interpretation of risk vs reward. We constantly make this decision in our work and personal lives. Its human nature.

Most statistics back up the triangle but can only be properly seen if the workplace has a strong reporting culture.

A lot of hazards and near misses are never reported so the actual near misses and at risk behaviours may be a lot higher in frequency than the above triangle.

We can’t accept at risk behaviours as once a precedent is set, others will follow the lead especially if those who cut corners receive positive feedback based on output or production improvements.

Safety in design of plant equipment

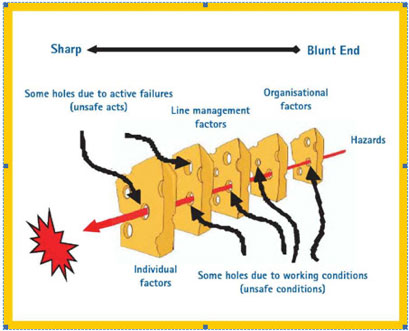

Figure 2 – James Reason’s Swiss Cheese Model of Accident Causation

The remaining causes of significant events stems from the mechanical, engineering safety in design of plant or equipment. Often we are unaware there is a potential flaw in the design, process or engineering which leads to catastrophic events that make the news.

What we can do is not accept flaws in the function or structure of the tools, equipment, or plant by checking them rigorously before and during use.

Unsafe processes or procedures

Finally, the last cause of events stems from unsafe processes or procedures of completing a task. Most procedures in our workplaces have been developed over the years, often borrowed from other organisations and altered to fit the working environment, but almost all have been developed due to the result of a workplace incident. Learning by our mistakes.

Procedures are developed with the intention to educate those doing the actual job and allow reference in case people are unsure. Procedures also set the consistent standard, demanded by the employer that the workers are required to abide by as per workplace safety legislation.

Keeping documents current and understandable

What you can do is; take time to understand the company documents. Base your tasks according to the documented processes and make sure you are utilising the latest version of the document. Question the document by speaking to your supervisor, if there is an error or you don’t agree with it, speak up. You may be saving you and your workmates grief in the future.

Think about how you would educate your kids, younger sibling, or mate who has just started on the job.

You are not going to teach them or demonstrate unsafe behaviours because you know that will put them at risk.

We require you to go one step further and make an effort to look critically at the workplace, do you pre starts, participate in the safety observation program and complete the required supervisor inspections.

REPORT WHAT YOU SEE!

It does take time, but it takes more time to fix or investigate something if it’s actually gone wrong. Supervisors must remain vigilant to educate the workforce and promote best practice at all times; this is the core function of the position.

If behaviours, hazards and events are reported correctly, we can develop strategies to ensure they don’t escalate or repeat. That’s how we improve workplace safety. Looking out for yourself and your workmates and working as a team to demonstrate effective and safe work practices.

Should you require assistance in culture change related to incident reporting contact us:

Tell: 08 6311 7043

Email: cservice@ussaglobal.com

The post The Importance of Reporting Events, Hazards and Near Misses appeared first on USSA Global.

]]>The post Safety Slogans appeared first on USSA Global.

]]>Accidents in the workplace are an unfortunate occurrence, but can be prevented with some foresight. Many Health and Safety departments have long since tried to find the perfect way to ensure the safety of workers that is not only easy, but also cost affordable. However, it can be difficult to determine where that foresight can lead to. But even with foresight on one’s side, humans are still infallible, with limited perception and memory to completely encompass all of the safety rules of the workplace that have been laid out for them.

That is where safety slogans come in handy. In areas of the workplace that are constantly at risk of being filled with hazards, misuse of dangerous equipment, and the element of human error, safety slogans can make it very easy for workers to remember the element of risk involved with the task at hand and take the necessary precautions to prevent any harm from coming to their person or someone else.

The Use of Anagrams in Safety Slogans

Many companies turn away from the use of anagrams in slogans, believing them to be too cheesy to be taken seriously. However, these simple words can make it easy for workers to remember the safety protocols in place before they start working in order to ensure the maximum safety standard has been met for everyone involved in the task.

Safety slogans should be easy to recite, with the key factors of the safety protocols making up the brunt of its contents. They are useful tools wherever safety is concerned in reminding workers about the actions that need to be taken in preventing an accident from occurring. Safety slogans placed on signs around the hazardous area of work is a sure way of ensuring that these protocols are adhered to and crises are averted. Having a worker try to recall a long list or rules while on the job is next to impossible, so it’s essential to make it as easy as possible for safety slogans to be easy to remember.

The post Safety Slogans appeared first on USSA Global.

]]>The post Common Workplace Hazards for Office Workers appeared first on USSA Global.

]]> There are many workplace hazards that can be found around the typical Australian office. Poor posture when working at a computer along with excessive time spent in an office chair can cause physical injury to an employee’s arms, neck and shoulders. Eye strain is another commonly reported injury. Computers also pose a threat in the form of electric shocks. Employees when using computers are always at risk of electrical fault occurring that may result in fires or burns to the skin. Furthermore, power cords needed to keep computers powered on are able to be tripped over, causing twisted ankles or fractures.

There are many workplace hazards that can be found around the typical Australian office. Poor posture when working at a computer along with excessive time spent in an office chair can cause physical injury to an employee’s arms, neck and shoulders. Eye strain is another commonly reported injury. Computers also pose a threat in the form of electric shocks. Employees when using computers are always at risk of electrical fault occurring that may result in fires or burns to the skin. Furthermore, power cords needed to keep computers powered on are able to be tripped over, causing twisted ankles or fractures.

Employees that work with other types of office equipment such as photocopiers and printers present the risk of exposure to printer toner which can cause irritation or damage to the eyes and skin. These equipment types, along with fax machines and other peripheral devices, can be workplace hazards that have potential to give anyone an electric shock. OH&S regulations work to minimise these risks by ensuring that machines such as photocopiers are located in well-ventilated places. Machines are also consistently checked to be safe for use by having regular test and tagging procedures completed.

Many workplace hazards also stem from the use of paper shredders, guillotines and laminators when performing regular office duties. These, like electrical equipment, can also cause harm if not handled correctly. They contain sharp edges, hot surfaces as well as pinch points that across the country have resulted in several cuts and minor physical injuries to employees. To avoid these mishaps, a workplace should ensure quality training is provided to all office workers who must use them, making sure to remind all employees that loose clothes and jewellery can get caught in this equipment.

Offices hazards in Australia have also included such things as items falling of shelved surfaces onto nearby employees. This can be prevented by allowing for adequate storage spaces to ensure shelves are not over-filled to raise the risk of injury.

The post Common Workplace Hazards for Office Workers appeared first on USSA Global.

]]>The post Worksafe: WA model WHS legislation on its way appeared first on USSA Global.

]]>To read the full article and for further information about the bill, click here: http://www.commerce.wa.gov.au/announcements/work-health-and-safety-legislation

The post Worksafe: WA model WHS legislation on its way appeared first on USSA Global.

]]>The post National work health and safety guidance material released appeared first on USSA Global.

]]>- Workplace traffic management

- Managing cash-in-transit security risks

- Managing risks in forestry operations

- Industrial lift trucks

- Amusement devices

- Safe design, manufacture, import and supply of plant

- Working in the vicinity of overhead and underground electric lines

- Formwork and falsework

- Scaffolds and scaffolding work.

The national material provides practical advice for persons conducting a business or undertaking on how to manage risks at the workplace. The material includes information sheets to assist small businesses and workers meet their WHS obligations.

The national guidance material was agreed by majority by Safe Work Australia Members in June 2014.

To read the full article and access the guidance material, click here: http://www.safeworkaustralia.gov.au/sites/swa/news/pages/tn04072014

The post National work health and safety guidance material released appeared first on USSA Global.

]]>The post Lowest number of work-related deaths in 11 years appeared first on USSA Global.

]]>The annual report found that 191 workers died from injuries received at work in 2013.

Distressingly, the fatality rate for self-employed workers (4.39 deaths per 1000 000 selfemployed workers) was three times higher than the fatality rate for employees (1.31). This is partly due to the high fatality rates in the Agriculture, forestry and fishing and Transport, postal and warehousing industries, both of which also have a higher than average proportion of selfemployed workers.

To read the full article, click here: http://www.safeworkaustralia.gov.au/sites/SWA/media-events/media-releases/Documents/2014%20Media%20Releases/MR15072014-Lowest-work-related-deaths-in-eleven-years.pdf

The post Lowest number of work-related deaths in 11 years appeared first on USSA Global.

]]>The post Dumb Ways to Die appeared first on USSA Global.

]]>The post Dumb Ways to Die appeared first on USSA Global.

]]>The post Yara Pilbara chief calls for industry-wide safety training appeared first on USSA Global.

]]>Yara Pilbara chief executive Mark Loquan has called for industry standardised safety training for mine site workers in Western Australia.

Mr Loquan raised the idea at the Chamber of Minerals and Energy health and safety conference in Perth on Monday morning.

He told delegates that the onshore sector is lagging behind the offshore industry in achieving across-industry minimum safety standards for contractors.

“I am in no way questioning the commitment to safety across the sector and by the contractors, but I am concerned there are no agreed minimum standards that apply across the onshore processing industry,” Loquan said.

“Currently it’s somewhat fragmented, with individual companies having their own systems and requirements but the industry has a highly mobile workforce. This can yield unpredictable outcomes in the industry.”

Mr Loquan said Yara Pilbara, operator of the world’s largest ammonia production facility near Karratha, had successfully embarked on a program to improve occupational and process safety performance.

Yara Pilbara claims to have attained over 800 days without a “recordable” injury for employees or contractors, leading up to February 2014.

“Although we have a permanent residential workforce, like many operators we have a strong reliance on contractors for certain tasks and we take our duty of care very seriously. We do wish to continuously raise the bar on safety, which can only benefit all workers entering our site to return home safely to their families.”

Loquan said he supported the introduction of a co-ordinated contractor safety system such as that implemented offshore in Australia by APPEA, which he had also seen operating in Trinidad and Tobago’s petrochemical industry.

Loquan said through a collaborative approach in Trinidad and Tobago several onshore processing companies, the country’s Energy Chamber, contractors and industry bodies had developed a “passport” system, like the construction industry nationally recognised White Card.

“I think as an industry we need to possibly collaborate more for the long term and to acknowledge the need for minimum standards. In this way, we can get on with working together to put a robust system in place to improve occupational safety for contractors,” Loquan said.

He said Yara Pilbara had been using the construction industry White Card as a standard and had also been discussing with APPEA the possibility of modifying the Common Safety Training Program (CSTP) card for the offshore platforms and applying it to the company’s WA plants.

The post Yara Pilbara chief calls for industry-wide safety training appeared first on USSA Global.

]]>The post Citigroup: Worker safety a focus for investors appeared first on USSA Global.

]]>A recent article in the Canberra Times states ‘Mining companies need to maintain the highest safety standards for their employees or risk a potential shareholder backlash, according to one of the country’s largest investment research firms.

As the Austar Coal Mine in the Hunter Valley investigates the death of two miners due to a wall collapse at its coalmine near Paxton, the managing director and head of research at Citigroup Australia and New Zealand, Bruce Rolph, said company safety records and reputations were playing an increasingly large part in their commercial success.

Citigroup’s research wing conducts yearly analyses of the safety records of Australia’s top-performing listed companies – this year finding 427 employees had been killed in industrial accidents since 2005 – most commonly in the mining industry.

That figure rose to 523 when members of the public were included in the accident count.

Advertisement

The report, Safety Spot-light, ASX 100 Companies and More, has been updated each year since 2009, and captures data on 117 top companies. Other dangerous industries include construction, engineering, transport and logistics.

Mr Rolph said the real force for change in making companies more accountable for their safety practices were institutional investors, fund managers and superannuation funds, who were increasingly focusing on ethical, social and environmental practices of top companies.

“Some years ago they may have been giving lip service to these issues, as they couldn’t be seen not to support them, but these days it is seen as a material market-influencing factor in investment decisions,” he said.

Mum and dad investors were also making their views clear – avoiding companies with poor safety record just as they avoided gaming and tobacco companies.

“Accidents happen but people want increasing confidence that companies take as much effort as possible to reduce those accidents to only those things which cannot be avoided,” Mr Rolph said.

The most recent report singled out Leighton Holdings, Lend Lease, Rio Tinto, Orica, Coca-Cola Amatil, Newcrest Mining, BHP Billiton, Boral, Aquarius Platinum, Toll Holdings and Transfield Services for having more than 10 deaths since 2005.

Mining giants Rio Tinto and BHP Billiton had the most deaths, losing 48 and 45 employees respectively.

Construction and infrastructure company Leightons lost 41 employees, while construction and property company Lend Lease lost 40.

Lend Lease was the company involved in the Canberra death in 2006 of father of two Nik Spasovski, 48, who fell to his death through an uncovered hole on the 11th floor of the Australian Taxation Office as it was being constructed.

But the Citi analysis also shows deaths, accidents and lost hours to injury are slowly decreasing.

It found that in the past year, 50 companies out of 78 reported a decline in lost time to injury rates, while 31 companies reported a decline in the injury frequency rate.

Construction, Forestry, Mining, and Energy Union ACT Secretary Dean Hall said it was heartening that shareholders and investors were taking note of company safety records, but devastating to learn of the loss of the two Hunter miners.

“This report understands that when there is a fatality, not only is it a terrible tragedy for the families involved, but that accidents can slow production and affect profits, so it is in the company’s best interests to stop the death toll,” he said.

Mr Hall said Lend Lease’s safety record was highly questionable. “Forty people dead. Well, if we were involved in a peacekeeping mission overseas and we lost 40 soldiers, the Australian government would be removing our armed forces from the war zone, no question.

“Workers are not given that same consideration.”

The post Citigroup: Worker safety a focus for investors appeared first on USSA Global.

]]>