The post Independent Incident Investigations appeared first on USSA Global.

]]>Hiring an external third party will also remove any potential subjectivity and therefore help ensure that any investigation has the perception by the workforce and clients/ customers as being objective and independent. Providing a fresh set of eyes can also help in improving all aspects of safely in the workplace. When conducting Independent Incident Investigations, our experienced investigators will liaise with the workforce, manage the investigating authorities and ensure that the outcome of the investigation remains independent and objective.

USSA Global can help support your organisation immediately after an incident, as well as managing the data collection and subsequent investigation. We have the capacity to provide fully trained and experienced incident investigators at short notice, to run independent incident and ICAM* /Taproot investigations or, if preferred, support senior management in undertaking detailed internal investigations.

USSA Global can help support your organisation immediately after an incident, as well as managing the data collection and subsequent investigation. We have the capacity to provide fully trained and experienced incident investigators at short notice, to run independent incident and ICAM* /Taproot investigations or, if preferred, support senior management in undertaking detailed internal investigations.

Western Power approved Independent Investigators

When serious incidents occur in companies such as Western Power, USSA Global provide the independent incident investigation. These companies know that a number of legal obligations need to be adhered to in terms of reporting and notification and USSA provides this service in a concise independent and objective manner.

Independent Incident Investigations for Telstra

Independent Incident Investigations for Telstra

Another company that utilises USSA Global for Independent Incident Investigations is Telstra. They insist that any significant incidents that may occur are conducted by an objective external investigator – USSA Global.

Find out more about USSA’s Incident Investigations here: Incident Investigation

The post Independent Incident Investigations appeared first on USSA Global.

]]>The post The Importance of Reporting Events, Hazards and Near Misses appeared first on USSA Global.

]]>- You don’t really believe the event or hazard you saw is really that significant and is not worth the time and effort to report

- You don’t see the hazard or near miss escalating to the point someone will actually be injured

- You see a co-worker doing something in an unsafe way but, you inherently don’t like conflict and would feel uneasy speaking up

- You are busy and really don’t have time to stop and report things right now

- You believe that if you do report something, you are going to be tied up with the report and will be under more pressure once done to catch up on the work you should have been doing

And there are many, many more reasons.

At-Risk-Behaviour

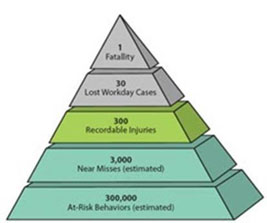

Figure 1 – Frank Bird Triangle

Frank Bird’s Tringle, was developed in the 1960’s. His conclusion was one thing led to another and ultimately resulted in something catastrophic eventually. His estimates of underlying at risk behaviours led to near misses and eventually events causing injury or harm to workers. Other researches explain a domino effect or the lining up of factors leading to an event.

Many have disputed this research and similar work by others but most people will agree the majority of workplace incident occurred because someone made a choice and that choice put them in danger. The choices we make are usually based on our interpretation of risk vs reward. We constantly make this decision in our work and personal lives. Its human nature.

Most statistics back up the triangle but can only be properly seen if the workplace has a strong reporting culture.

A lot of hazards and near misses are never reported so the actual near misses and at risk behaviours may be a lot higher in frequency than the above triangle.

We can’t accept at risk behaviours as once a precedent is set, others will follow the lead especially if those who cut corners receive positive feedback based on output or production improvements.

Safety in design of plant equipment

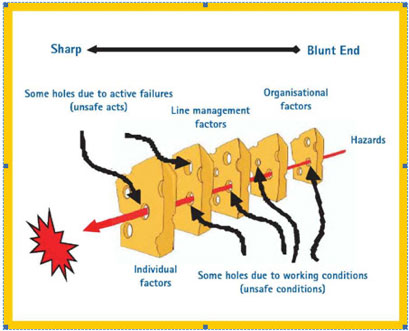

Figure 2 – James Reason’s Swiss Cheese Model of Accident Causation

The remaining causes of significant events stems from the mechanical, engineering safety in design of plant or equipment. Often we are unaware there is a potential flaw in the design, process or engineering which leads to catastrophic events that make the news.

What we can do is not accept flaws in the function or structure of the tools, equipment, or plant by checking them rigorously before and during use.

Unsafe processes or procedures

Finally, the last cause of events stems from unsafe processes or procedures of completing a task. Most procedures in our workplaces have been developed over the years, often borrowed from other organisations and altered to fit the working environment, but almost all have been developed due to the result of a workplace incident. Learning by our mistakes.

Procedures are developed with the intention to educate those doing the actual job and allow reference in case people are unsure. Procedures also set the consistent standard, demanded by the employer that the workers are required to abide by as per workplace safety legislation.

Keeping documents current and understandable

What you can do is; take time to understand the company documents. Base your tasks according to the documented processes and make sure you are utilising the latest version of the document. Question the document by speaking to your supervisor, if there is an error or you don’t agree with it, speak up. You may be saving you and your workmates grief in the future.

Think about how you would educate your kids, younger sibling, or mate who has just started on the job.

You are not going to teach them or demonstrate unsafe behaviours because you know that will put them at risk.

We require you to go one step further and make an effort to look critically at the workplace, do you pre starts, participate in the safety observation program and complete the required supervisor inspections.

REPORT WHAT YOU SEE!

It does take time, but it takes more time to fix or investigate something if it’s actually gone wrong. Supervisors must remain vigilant to educate the workforce and promote best practice at all times; this is the core function of the position.

If behaviours, hazards and events are reported correctly, we can develop strategies to ensure they don’t escalate or repeat. That’s how we improve workplace safety. Looking out for yourself and your workmates and working as a team to demonstrate effective and safe work practices.

Should you require assistance in culture change related to incident reporting contact us:

Tell: 08 6311 7043

Email: cservice@ussaglobal.com

The post The Importance of Reporting Events, Hazards and Near Misses appeared first on USSA Global.

]]>The post Common Workplace Hazards for Office Workers appeared first on USSA Global.

]]> There are many workplace hazards that can be found around the typical Australian office. Poor posture when working at a computer along with excessive time spent in an office chair can cause physical injury to an employee’s arms, neck and shoulders. Eye strain is another commonly reported injury. Computers also pose a threat in the form of electric shocks. Employees when using computers are always at risk of electrical fault occurring that may result in fires or burns to the skin. Furthermore, power cords needed to keep computers powered on are able to be tripped over, causing twisted ankles or fractures.

There are many workplace hazards that can be found around the typical Australian office. Poor posture when working at a computer along with excessive time spent in an office chair can cause physical injury to an employee’s arms, neck and shoulders. Eye strain is another commonly reported injury. Computers also pose a threat in the form of electric shocks. Employees when using computers are always at risk of electrical fault occurring that may result in fires or burns to the skin. Furthermore, power cords needed to keep computers powered on are able to be tripped over, causing twisted ankles or fractures.

Employees that work with other types of office equipment such as photocopiers and printers present the risk of exposure to printer toner which can cause irritation or damage to the eyes and skin. These equipment types, along with fax machines and other peripheral devices, can be workplace hazards that have potential to give anyone an electric shock. OH&S regulations work to minimise these risks by ensuring that machines such as photocopiers are located in well-ventilated places. Machines are also consistently checked to be safe for use by having regular test and tagging procedures completed.

Many workplace hazards also stem from the use of paper shredders, guillotines and laminators when performing regular office duties. These, like electrical equipment, can also cause harm if not handled correctly. They contain sharp edges, hot surfaces as well as pinch points that across the country have resulted in several cuts and minor physical injuries to employees. To avoid these mishaps, a workplace should ensure quality training is provided to all office workers who must use them, making sure to remind all employees that loose clothes and jewellery can get caught in this equipment.

Offices hazards in Australia have also included such things as items falling of shelved surfaces onto nearby employees. This can be prevented by allowing for adequate storage spaces to ensure shelves are not over-filled to raise the risk of injury.

The post Common Workplace Hazards for Office Workers appeared first on USSA Global.

]]>The post Fertiliser Company Fined Over Employee Finger Loss appeared first on USSA Global.

]]>Ravensdown Fertiliser Co-operative Limited has been fined $33,000 and ordered to pay reparation of $5,000 after an employee’s hand was pulled into a machine in its Napier packing plant.

In November 2013, Ravensdown storeperson Jackson Hawea, had the little finger on his left hand amputated to the first knuckle after it got caught in a ‘tripper’ machine.

Mr Hawea was attempting to fix a fault in the machine by applying tension to a wire cable in the tripper room. The machine was in operation at the time and the cable tightened itself as he touched it. The wire caught his hand and as he tried to pull it out the tip of his left little finger was sliced off.

A WorkSafe New Zealand investigation found that the machine was not adequately guarded to prevent workers accessing dangerous moving parts in the tripper room.

Ravensdown was convicted at the Napier District Court under Section 6 of the Health and Safety in Employment Act for failing to take all practicable steps to ensure the safety of its employees.

WorkSafe New Zealand’s Chief Inspector Keith Stewart says the loss of Mr Hawea’s finger was completely avoidable.

“Ravensdown is a major New Zealand company. Its health and safety systems should have identified this hazard and proper guarding should have been put in place to minimise the risk.

“Proper guarding of the dangerous moving parts of machines is basic stuff. Ravensdown should have ensured that guarding in the tripper room was up to scratch and in line with the Safety of Machinery Standards,” says Keith Stewart.

To read the full article click here

The post Fertiliser Company Fined Over Employee Finger Loss appeared first on USSA Global.

]]>The post South island company fined over rock crusher accident appeared first on USSA Global.

]]>William Clark was working as a labourer at a plant run by a company associated to Solly’s Freight, Golden Bay Dolomite Limited, in August last year when the incident occurred. He was attempting to clear debris away from one of the conveyor belts on a rock crusher when his glove got caught and his arm was dragged into the drum roller.

Mr Clark suffered cuts, crushing, a dislocated shoulder and a fracture to his upper arm.

Solly’s Freight pleaded guilty to two charges under the Health and Safety in Employment Act (sections 6 and 50) of failing to take all practicable steps to ensure Mr Clark’s safety at work. The company was sentenced today at the Nelson District Court.

WorkSafe New Zealand’s Chief Inspector, Keith Stewart, says the rock crusher should have had guards in place to prevent access to the dangerous parts of the machine while it was in operation.

WorkSafe NZ placed a prohibition notice on the use of the machine following the incident. Appropriate guards were subsequently put in place, and the notice was then lifted.

“Solly’s Freight also let itself and its workers down by not ensuring it had an effective hazard identification process in place.

“Mr Clark was never shown the standard operating procedures for the rock crusher or the manufacturer’s brochure. And he was not aware of any written procedures for the operation of the machine or the identification of its hazards.

“All companies – particularly those with dangerous machinery – need to make sure they systematically identify and manage health and safety risks,” says Keith Stewart.

To read the full article, click here: http://www.business.govt.nz/worksafe/news/releases/2014/company-fined-over-rock-crusher-accident

The post South island company fined over rock crusher accident appeared first on USSA Global.

]]>The post Auckland Roofers fined for Inadequate Scaffolding appeared first on USSA Global.

]]>WorkSafe New Zealand prosecuted Eden Homes Development after its employees Wei Qiang Sun and Ming Han were seen installing a roof in Glenfield without adequate edge-protection to help prevent falls. No accident actually occurred.

Eden Homes Development was yesterday fined $15,000 at the North Shore District Court for failing to take all practicable steps to ensure the safety of its employees.

Scaffolding at the site was incomplete, and only provided protection for the first level of the construction site. It was arranged by the homeowner, not Eden Homes Development.

WorkSafe NZ’s Chief Investigator, Keith Stewart, says making the pair work at height without the appropriate scaffolding put them at real and unacceptable risk.

“Eden Homes Development should have ensured the scaffolding and edge protection was complete and adequate before allowing work to commence. The contract for the project should either have included the provision of scaffolding by the company, or required the homeowner to install it before work could begin.

“What is more, the company also failed to provide its workers with any other equipment to protect them and minimise the risk of falls in the absence of proper edge protection.

“Eden Homes Development also should have had a clear policy that employees will not carry out work at height if edge or fall protection is not in place. Quite simply, the company failed its workers.

“It was only a matter of good luck rather than good management that no-one was hurt in this case. This prosecution serves as a strong reminder to everyone in the building industry of the importance of ensuring they have proper protections in place before beginning any work at height,” says Keith Stewart.

To read the full article, click here: http://www.business.govt.nz/worksafe/news/releases/2014/inadequate-scaffolding-leads-to-fine

The post Auckland Roofers fined for Inadequate Scaffolding appeared first on USSA Global.

]]>The post Rotorua Forestry death an avoidable tragedy appeared first on USSA Global.

]]>Robert Ruri-Epapara was working as part of a Complete Logging Limited logging crew at Waione Forest near Rotorua in March 2013 when he was fatally injured by a falling tree cut down by Major Nelson.

Mr Nelson was the crew’s foreman and was operating a Timberjack machine, which is a tracked excavator with an attachment used for felling trees. It is also used as an anchor point for cables used to haul logs up a slope.

Mr Nelson was attempting to manoeuvre the Timberjack onto a level position so it could be used as an anchor point, and decided to fell some trees that were in his way. He was unable to see Mr Ruri-Epapara, who was working without any radio communications on a steep slope with thick undergrowth.

Mr Nelson contacted another worker with a radio who could see up the slope to try to check on Mr Ruri-Epapara’s location. It is unclear exactly what Mr Nelson was told, but his understanding was that the slope was clear. He went ahead and cut down a tree which struck Mr Ruri-Epapara and another tree which also toppled over.

The fact that a second tree had fallen alerted Mr Nelson to the fact that someone may have been working in the area. He stopped the machine and went to check the area. When he found Mr Ruri-Epapara he began CPR but when emergency services arrived they confirmed his injuries were fatal.

Major Nelson was convicted under sections 19(b) and 50(1)(a) of the Health and Safety in Employment Act of failing to take all practicable steps as an employee to ensure that no action of his while at work caused harm to another person.

WorkSafe New Zealand’s chief investigator, Keith Stewart, says Mr Ruri-Epapara’s death was a tragedy that could have been avoided if the Code of Practice for Safety and Health in Forest Operations had been followed.

“Mr Nelson should have established the location of Mr Ruri-Epapara before he moved the Timberjack machine into his work area and began bringing down trees.

“Mr Nelson should also have made Mr Ruri-Epapara aware of what he was doing with the Timberjack so that he could move into a safe zone, at least two full tree lengths away from the tree being felled.

“Forestry as an inherently dangerous industry, and the Code of Practice is designed to save lives. There is no room for short-cuts and a ‘she’ll be right’ attitude. As foreman Major Nelson should have known better,” says Keith Stewart.

To read the full article, click here: http://www.business.govt.nz/worksafe/news/releases/2014/forestry-death-an-avoidable-tragedy

The post Rotorua Forestry death an avoidable tragedy appeared first on USSA Global.

]]>The post Company pleads guilty over Pilbara mine death appeared first on USSA Global.

]]>The matter was heard yesterday in South Hedland before Magistrate Potter.

Mr Kurt Williams, a contracted electrician with CSI, was greasing a motor when he was fatally crushed by a ladder attached to a tripper unit at the top of the ore processing facility at Fortescue Metal Group’s Christmas Creek mine.

CSI was charged under the Mines and Safety Inspection Act for failing to provide a safe working environment.

DMP’s Resources Safety Executive Director Simon Ridge said the guilty plea was a pleasing result for a very tragic matter.

“I am sure it will be a relief to the victim’s family that this court matter will not continue to be a protracted process,” he said.

“It should also serve as a reminder that safety needs to be the number one priority for everyone, especially mine operators.

“There is no room for complacency, every fatality or serious injury is one too many.

“The department will continue to work with mining operators to ensure WA operates to high safety standards, but in any instance where that is found not to be the case, the department will hold those responsible to account.”

The guilty plea was entered and the matter was adjourned until 19 September 2014 for sentencing.

To read the full article, click here: http://www.dmp.wa.gov.au/7105_20498.aspx

The post Company pleads guilty over Pilbara mine death appeared first on USSA Global.

]]>The post WA WorkSafe Offices relocated to Cannington appeared first on USSA Global.

]]>If you have any questions or need further information, call 1300 307 8771300 307 877 or email safety@commerce.wa.gov.au

To view the full article and for the latest updates on the moves, click here: http://www.commerce.wa.gov.au/corporate/commerce-offices-are-moving

The post WA WorkSafe Offices relocated to Cannington appeared first on USSA Global.

]]>The post Worksafe: WA model WHS legislation on its way appeared first on USSA Global.

]]>To read the full article and for further information about the bill, click here: http://www.commerce.wa.gov.au/announcements/work-health-and-safety-legislation

The post Worksafe: WA model WHS legislation on its way appeared first on USSA Global.

]]>